Top Features to Look for in an Arc Welding Machine

Introduction

Welding is an essential process in construction, manufacturing, and home projects, and choosing the right arc welding machine can greatly impact welding efficiency, safety, and quality. With numerous arc welding machines available in the market, selecting the best one requires careful evaluation of key features that influence performance, durability, and ease of use.

Whether you're a professional welder in an industrial setting or a DIY enthusiast working on home repairs, understanding the top features of an arc welding machine ensures you get maximum value and productivity from your investment.

In this guide, we’ll explore critical factors to consider when buying an arc welding machine, including power output, duty cycle, portability, welding compatibility, inverter technology, and safety features.

Read more...How to Choose the Best Welding Machine for Your Projects in Nigeria

Key Takeaway

- Power Output Matters – Choose a machine with the appropriate voltage and amperage to handle your specific welding tasks effectively.

- Duty Cycle is Crucial – A higher duty cycle means longer continuous operation, reducing downtime and improving efficiency.

- Portability and Size – Lightweight and compact machines are ideal for mobility, while stationary units suit industrial settings.

Kaierda inverter manual arc welding machine ZX7-630S

Key Features to Look for in an Arc Welding Machine

Power Output (Amperage Range & Voltage)

The power output of an arc welding machine determines the type and thickness of metals it can weld effectively.

- Low Amperage (50A–200A) – Ideal for home welding, light fabrication, and automotive repairs.

- High Amperage (200A–630A) – Best for industrial applications, heavy fabrication, and structural welding.

Additionally, voltage requirements differ between machines:

- 110V or 220V (Single-phase) – Suitable for home and small workshop use.

- 380V (Three-phase) – Designed for high-power industrial welding applications.

Example: The Kaierda ZX7-630S Arc Welding Machine delivers an output range of 50A-630A, making it ideal for large-scale industrial welding projects that require deep penetration on thick materials.

Read more...Revolutionizing Industrial Processes with Arc Welding Machines: A Comprehensive Guide

Duty Cycle & Performance Efficiency

The duty cycle of a welding machine is the amount of time it can operate within a 10-minute cycle before requiring a cooldown.

- Short Duty Cycle (20%–40%) – Suitable for home welding and occasional light repairs.

- Extended Duty Cycle (60%–100%) – Ideal for continuous welding in industrial settings where overheating must be avoided.

Example: The Kaierda ZX7-630S offers a 100% duty cycle at 520A, allowing extended operation without interruptions, making it a perfect choice for professional welders.

Welding Process Compatibility (Stick, MIG, TIG, Flux-Cored)

Different welding jobs require different processes. Selecting a multi-process welding machine enhances flexibility and efficiency.

- Stick Welding (SMAW) – Works best for outdoor, industrial, and heavy-duty metal welding.

- MIG Welding (GMAW) – Provides clean, fast welds, making it ideal for sheet metal fabrication.

- TIG Welding (GTAW) – Best for precision welding on materials like aluminum and stainless steel.

- Flux-Cored Welding (FCAW) – Works well in windy outdoor conditions and requires no external shielding gas.

Tip: If you need versatility, opt for a dual-process or multi-process welder that supports Stick and TIG welding.

Kaierda Inverter/Arc Welding machine ZX7-200N/220V/DC

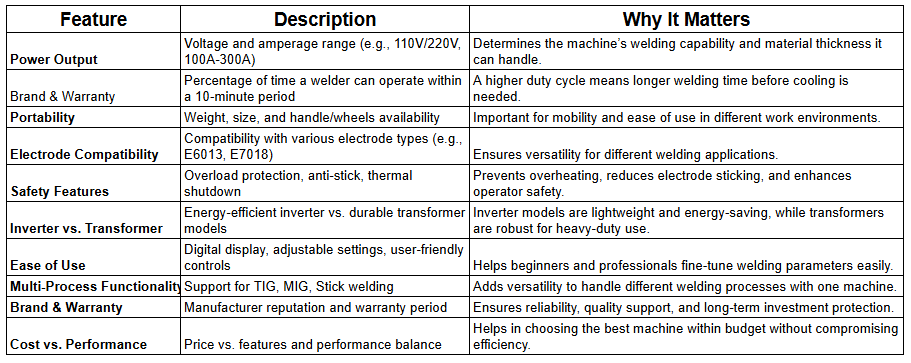

Comparison Table: Top Features to Look for in an Arc Welding Machine

Inverter vs. Transformer Technology

Arc welding machines come with two primary power technologies:

Inverter Welders

- Compact, lightweight, and energy-efficient.

- Delivers smoother arc control, making it ideal for precision welding.

- Best for portable fieldwork, home use, and automotive repairs.

Transformer Welders

- Heavier, more durable, and built for industrial use.

- Handles higher amperages for continuous welding operations.

- Best for large-scale factory production and heavy-duty fabrication.

Example: The Kaierda ZX7-200N Arc Welding Machine is an inverter welder, offering stability and energy-saving benefits for home and small-scale industrial applications.

Portability & Weight

Portability is an important feature, especially for welders who move between job sites or require a compact machine for small workshops.

- Lightweight Welders (5-15kg) – Ideal for home welding, mobile repairs, and fieldwork.

- Heavy-Duty Welders (50kg and above) – Best for industrial settings with stationary welding stations.

Example: The Kaierda ZX7-200N weighs only 7kg, making it a perfect choice for welders who need a portable and mobile welding machine.

Kaierda Inverter DC MMA Welding Machine ZX7-315N

Digital Display & User Controls

Modern welding machines feature advanced digital controls to improve precision, ease of use, and overall welding accuracy.

- Digital Amperage & Voltage Display – Allows for precise power adjustments for different welding applications.

- Preset Welding Modes – Makes it easier for beginners to select the right settings for various metals.

- Simple Knob & Button Interface – Ensures quick and seamless adjustments during welding operations.

Tip: A welding machine with an intuitive digital display enhances efficiency and ease of operation, especially for precision welding tasks.

Arc Stability & Performance

A stable arc is essential for consistent welds with minimal spatter. Look for arc welding machines that offer arc stability-enhancing features:

- Hot Start Technology – Provides a strong arc ignition, reducing electrode sticking.

- Anti-Stick Function – Prevents electrodes from sticking to the metal workpiece.

- Arc Force Control – Automatically adjusts the arc to maintain a stable weld pool, even in demanding conditions.

Example: The Kaierda ZX7-630S provides exceptional arc stability, making it ideal for professional and industrial welding applications.

Safety Features

Safety should always be a top priority when selecting an arc welding machine. Many machines come with built-in safety measures to prevent electrical hazards, overheating, and accidents.

- Overheat Protection – Automatically shuts down the welder if it exceeds safe operating temperatures.

- Overload & Voltage Surge Protection – Prevents power surges that could damage electrical components.

- Cooling Fans & Thermal Management – Helps the machine run efficiently without overheating.

Tip: Always choose a welding machine with integrated safety features to prevent workplace accidents and equipment damage.

Kaierda Inverter TIG/MMA Welding Machine WS-T250S

Frequently Asked Questions

1. What are the key factors to consider when buying an arc welding machine?

When purchasing an arc welding machine, consider factors like power output, duty cycle, electrode compatibility, portability, safety features, and the type of welding you will be performing.

2. What is the importance of the duty cycle in an arc welding machine?

The duty cycle indicates how long a welding machine can operate continuously before it needs to cool down. A higher duty cycle is essential for heavy-duty industrial welding tasks.

3. Which type of arc welding machine is best for beginners?

For beginners, an inverter arc welding machine with an adjustable current setting and built-in safety features is recommended. These machines are lightweight, energy-efficient, and easier to operate.

4. How does an arc welding machine ensure safety during welding?

Modern arc welding machines come with safety features such as overload protection, thermal shut-off, and voltage fluctuation resistance to prevent electrical hazards and overheating.

5. Where can I buy high-quality arc welding machines in Nigeria?

You can find top-quality arc welding machines at Tikweld Welding Supplies, a trusted supplier of welding equipment and industrial tools.

Related Articles

How to Set Up and Use an Arc Welding Machine Like a Pro

Kaierda ZX7-200N Arc Welding Machine: Lightweight, Portable and Efficient for Welding Tasks

Conclusion

Choosing the right arc welding machine is crucial for ensuring efficiency, safety, and durability in welding projects. Whether you're a professional welder or a beginner, selecting a machine with the right power output, duty cycle, portability, and safety features will greatly impact your work quality.

For top-quality arc welding machines and accessories, visitTikweld Welding Supplies today and explore a wide range of reliable welding solutions tailored to your industrial needs!