Drilling Machines in Construction: Essential Tools for Professionals

Introduction

Drilling machines are indispensable tools in the construction industry, playing a crucial role in various structural and foundational processes. Whether it's for creating deep foundations, tunneling, or reinforcing structures, heavy-duty drilling machines provide efficiency, precision, and reliability. Professionals in construction rely on these powerful machines to complete projects on time and within budget. This article explores the different types, applications, and features of heavy-duty drilling machines, helping construction experts make informed decisions about the best tools for their projects.

Read more...Drilling Machine Parts: A Complete Guide

Key Takeaway

- Versatility: Drilling machines are essential for a wide range of construction tasks, from creating holes for foundations to installing fixtures and fittings.

- Power and Precision: Modern drilling machines, like rotary drills and hammer drills, offer high power and precision to handle tough materials like concrete and steel.

- Time Efficiency: These machines significantly reduce the time required for drilling tasks, making construction projects more efficient and cost-effective.

DongCheng Electric Impact Drill DZJ02-13

Understanding Drilling Machines in Construction

What Are Drilling Machines?

Drilling machines are mechanical devices designed to create holes in various materials, including concrete, metal, and rock. In construction, these machines are used for heavy-duty applications that require power, stability, and precision. They come in various forms, each tailored for specific tasks within the industry.

Key Components of Drilling Machines

Drilling machines typically consist of the following components:

- Drill Bit: The cutting tool that penetrates the material.

- Motor or Engine: Provides the necessary power to rotate the drill bit.

- Chuck: Holds and secures the drill bit in place.

- Feed Mechanism: Controls the depth and pressure applied during drilling.

- Base or Frame: Provides stability to prevent unnecessary movement during operation.

Heavy-Duty vs. Light-Duty Drilling Machines

While light-duty drilling machines are used for minor construction tasks such as electrical installations and cabinetry work, heavy-duty drilling machines are essential for large-scale projects. These machines are built for durability, handling tough materials such as reinforced concrete, bedrock, and steel with ease.

Types of Heavy-Duty Drilling Machines

Rotary Drilling Machines

Rotary drilling machines are designed for deep drilling into rock and soil. They utilize a rotating drill bit to break down material and are commonly used in foundation work, oil and gas exploration, and large-scale construction projects.

Percussion Drilling Machines

Also known as cable tool drilling, percussion drilling machines use repeated hammering actions to break through rock and other hard materials. They are often used for well drilling and geological explorations.

Hammer Drills & Rotary Hammers

These machines combine rotary motion with a hammering function to break through tough surfaces like concrete and masonry. They are widely used in construction for installing rebar anchors, breaking up old concrete, and preparing surfaces for further work.

Auger Drills

Auger drills use a helical screw blade to remove material as they drill. These are particularly useful for soil drilling, foundation piling, and installing utility poles. They are efficient in softer ground but can also handle compacted soil and clay.

Pile Drilling Rigs

These large-scale machines are essential for drilling deep foundations and creating stable supports for skyscrapers, bridges, and offshore platforms. They are capable of drilling through rock, clay, and sediment with high precision.

Diamond Core Drills

Diamond core drills are used for drilling through extremely hard materials like reinforced concrete and rock. These drills use diamond-tipped bits for precision cutting and are commonly used in high-strength infrastructure projects.

Maxmech Electric Drill ED 750-13

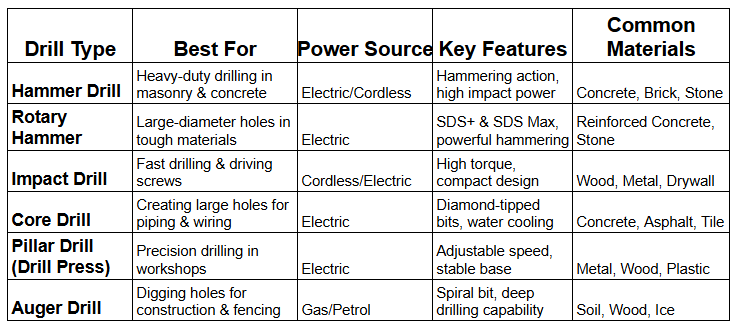

Comparison of Drilling Machines for Construction Applications

Read more...Drilling Machines vs. Milling Machines: Key Differences

Applications of Heavy-Duty Drilling Machines in Construction

Foundation Drilling and Piling

One of the most critical applications of drilling machines is in foundation construction. Piling rigs and rotary drilling machines create deep holes for reinforced concrete piles that provide structural stability for buildings and bridges.

Road and Bridge Construction

Drilling machines play a key role in the construction and maintenance of roads and bridges. They are used to create drainage systems, anchor reinforcements, and install support structures in complex terrains.

Tunnel and Underground Drilling

Tunnels for transportation, utilities, and mining require precision drilling to create passageways. Heavy-duty drills like rotary and percussion machines enable engineers to bore through rock efficiently.

Mining and Quarrying Applications

In mining and quarrying, drilling machines are used to extract valuable minerals from the earth. These machines must withstand harsh conditions and offer high penetration rates to improve productivity.

Structural Reinforcement and Retrofitting

Drilling machines play a vital role in strengthening existing structures. They help in retrofitting old buildings by drilling into concrete and steel to install reinforcements, ensuring longevity and safety.

Utility Installations (Electrical, Plumbing, HVAC)

Construction projects require precise drilling for installing electrical conduits, plumbing systems, and HVAC units. Heavy-duty drills ensure clean and accurate holes for seamless integration of these utilities.

Read more...Eco-Friendly Drilling Machines: Green Solutions for a Sustainable Future

DongCheng Cordless Brushless Driver/Hammer Drill 13mm 20V/4Ah DCJZ05-13EM

Key Features and Advancements in Modern Drilling Machines

High-Power Motors and Torque Control

Modern drilling machines are equipped with powerful motors and advanced torque control systems to handle the toughest materials with ease. These features ensure efficient drilling and reduce wear on drill bits.

Automation and Precision Drilling Technology

With advancements in automation, drilling machines now feature programmable settings and real-time monitoring systems, allowing for precision drilling with minimal manual intervention.

Enhanced Safety Features and Operator Comfort

New drilling machines come with safety mechanisms such as anti-kickback technology, emergency shut-off systems, and vibration reduction features to protect operators from fatigue and injuries.

Sustainability: Energy Efficiency and Reduced Environmental Impact

Manufacturers are focusing on eco-friendly drilling machines that consume less fuel and produce lower emissions. Electric and hybrid drilling machines are becoming more popular in the industry.

Smart Technology Integration (IoT, AI-Assisted Drilling)

The integration of IoT and AI in drilling machines enables real-time data collection, predictive maintenance, and enhanced performance tracking, leading to increased efficiency and reduced downtime.

Frequently Asked Questions

1. What is the most commonly used drilling machine in construction?

Rotary drilling machines are widely used due to their versatility and ability to drill deep into rock and soil.

2. How do I choose the right drilling machine for my project?

Consider the material, depth, precision requirements, and available power sources to select the most suitable drilling machine.

3. Are modern drilling machines energy efficient?

Yes, many modern drilling machines incorporate energy-efficient technologies, including electric and hybrid power options.

4. What safety precautions should be taken when using drilling machines?

Operators should wear protective gear, follow manufacturer guidelines, and use machines with safety features like emergency shut-off switches.

5. Where can I purchase high-quality drilling machines for construction?

For a wide selection of premium drilling machines, visitTikweld Welding Supplies to find the best tools for your construction needs.

Related Articles

Drilling Machine Troubleshooting: Common Problems and Solutions

Best Drilling Machine for Home Use

HOW TO USE A MAGNETIC DRILLING MACHINE

Conclusion

Drilling machines are indispensable tools in the construction industry, offering power, precision, and efficiency for a wide range of tasks. Whether you’re drilling into concrete, metal, or wood, choosing the right machine ensures faster project completion, reduced labor costs, and enhanced safety on-site.

Investing in high-quality, durable drilling machines not only boosts work efficiency but also guarantees long-term reliability for professional construction work. By selecting the right type of drill and following proper maintenance practices, construction professionals can maximize performance and extend equipment lifespan.

For top-quality drilling machines and accessories, visit Tikweld Welding Supplies and equip yourself with the best tools for the job!