Affordable Welding Equipment for SMEs in Nigeria

Introduction

Welding is an essential process in industries such as construction, automotive, metal fabrication, and pipeline works. For small and medium-sized enterprises (SMEs) in Nigeria, having cost-effective, high-quality welding equipment is crucial for business success. However, many SMEs face challenges in finding affordable, durable, and efficient welding machines that fit their budget.

Investing in the right welding equipment can help businesses improve productivity, reduce operational costs, and increase profit margins. In this guide, we’ll explore the best affordable welding equipment, essential accessories, where to buy them in Nigeria, and tips on maintaining your welding equipment to ensure long-term use.

Read more...The Ultimate Guide to welding and fabrication services in Nigeria

Key Takeaway

- Cost-Effective Options – SMEs can find high-quality yet affordable welding equipment to meet their operational needs.

- Essential Welding Tools – Basic welding machines, protective gear, and accessories are crucial for small-scale businesses.

- Durability and Performance – Investing in reliable brands ensures longevity and efficiency, reducing frequent replacement costs.

- Energy Efficiency – Choosing energy-efficient welding machines helps lower operational expenses.

Kaierda Tig Welding machine WS200N

Key Factors to Consider When Buying Affordable Welding Equipment

Budget and Cost-Effectiveness

For SMEs, it’s important to balance affordability with quality when choosing welding equipment. Extremely cheap welding machines may lack durability and efficiency, leading to frequent breakdowns and higher maintenance costs in the long run.

Tips for Cost-Effective Welding Equipment Purchases:

- Compare brand-new vs. refurbished welding machines.

- Consider total cost of ownership, including energy consumption and maintenance costs.

- Look for warranty and after-sales support when purchasing.

Type of Welding Process Suitable for SMEs

Choosing the right welding process is crucial for cost savings and efficiency. Here are the most common types of welding for SMEs:

MIG Welding (Metal Inert Gas)

- Best for speed and ease of use.

- Ideal for automotive, fabrication, and light industrial work.

- Requires a gas cylinder, which adds to costs.

TIG Welding (Tungsten Inert Gas)

- Best for precision work on stainless steel and aluminum.

- Ideal for decorative and high-quality welding.

- Slower process but produces clean, high-strength welds.

Stick Welding (Shielded Metal Arc Welding - SMAW)

- The most cost-effective welding method.

- Ideal for outdoor and structural work.

- Does not require shielding gas, reducing overall costs.

Multi-Process Welders

- Machines that support MIG, TIG, and Stick welding in one unit.

- Versatile option for SMEs handling different projects.

Power Requirements and Energy Efficiency

Nigerian SMEs must consider power supply limitations when choosing welding equipment.

Key Considerations:

- Single-phase vs. Three-phase welding machines – Single-phase (220V) is more common in small workshops, while three-phase (380V) is ideal for industrial settings.

- Energy-efficient welders – Look for inverter-based welding machines to reduce electricity consumption.

- Backup power options – Consider using an inverter or generator to ensure welding operations continue during power outages.

Tip: Energy-efficient welders reduce electricity bills, making them ideal for small businesses.

Maxmech Inverter Welding Machine TIG/MMA-250S

Portability and Space Considerations

Many SMEs operate in small workshops or require on-site welding services. Choosing portable welding machines allows for easy mobility and increases business opportunities.

Best Welding Machines for Portability:

- Inverter welding machines – Lightweight, energy-saving, and compact.

- Welding machines with built-in gas tanks – Reduce external component costs.

- Plasma cutters with portable designs – Ideal for on-the-go metal cutting.

Tip: Portable welding machines are great for mobile welding services, allowing SMEs to take on diverse projects.

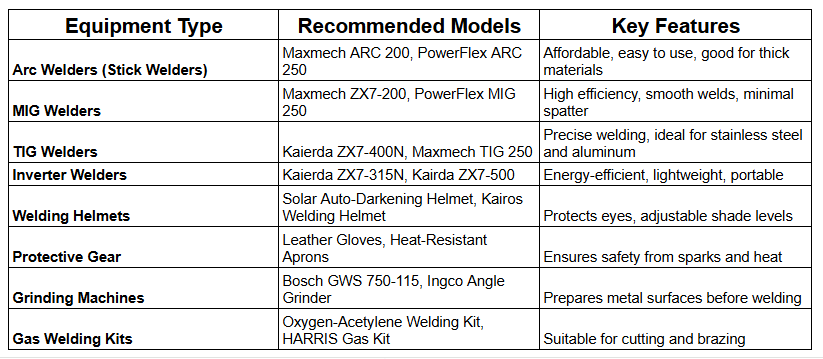

Budget-Friendly Welding Equipment for SMEs in Nigeria

Read more...The Most Affordable Air Compressors in Nigeria for Industrial Applications

Best Affordable Welding Machines for SMEs in Nigeria

Budget-Friendly MIG Welders

MIG welders are ideal for SMEs looking for fast and easy welding solutions.

Advantages:

- Faster welding speed.

- Good for thin and medium-thickness metals.

- Easy to learn and operate.

Affordable MIG Welders Available in Nigeria:

- Maxmech MIG-200 – Budget-friendly, energy-efficient.

- Cost-Effective Stick Welders (SMAW)

Stick welders are the most affordable and durable option for small businesses.

Advantages:

- Works well in outdoor and rough environments.

- No need for expensive shielding gas.

- Great for structural and general repair work.

Best Affordable Stick Welders for SMEs:

- Kaierda ZX7-500N – Perfect for general fabrication.

INGCO Auto Darkening Welding Helmet AHM008

Multi-Process Welders for Versatility

Multi-process welders are perfect for SMEs handling different projects with limited resources.

Advantages:

- Supports MIG, TIG, and Stick welding in one unit.

- Saves space and money by eliminating the need for multiple machines.

Recommended Multi-Process Welders for SMEs:

- Kaierda ZX7-315N

Plasma Cutters for Small Workshops

For SMEs involved in metal fabrication, a plasma cutter can significantly improve efficiency and precision. Plasma cutting is faster and more precise than using traditional saws or oxy-fuel cutting, making it an excellent investment.

Advantages:

- Cuts mild steel, stainless steel, and aluminum with precision.

- Low operational cost compared to oxy-fuel cutting.

- Portable models available for fieldwork.

Read more...Guide to Plasma Cutting Machines: Essential Tips for Fabricators

Essential Welding Accessories for SMEs

Apart from the welding machines, SMEs also need affordable but essential welding accessories to ensure efficiency, safety, and high-quality work.

Welding Helmets and Safety Gear

Welding without proper protective gear can result in injuries from sparks, UV radiation, and toxic fumes.

Budget-Friendly Safety Gear Options:

- Auto-darkening welding helmets – Protect against arc flash and improve visibility.

- Welding gloves – Heat-resistant gloves for MIG, TIG, and Stick welding.

- Flame-resistant jackets – Protect against burns from sparks and hot metal.

Tip: Invest in long-lasting safety gear to prevent injuries and workplace accidents.

Welders welding Jacket Leather

Welding Electrodes and Consumables

SMEs must carefully select the right electrodes and filler materials based on the type of welding they do.

Affordable Consumables for SMEs:

- Sureweld welding rods – Great for general-purpose stick welding.

- Flux-cored wire for MIG welding – Provides cost-effective, gasless welding.

- TIG filler rods – For precise, high-quality stainless steel welding.

Tip: Buy welding consumables in bulk to save money.

Welding Clamps and Fixtures

Holding metal pieces in place while welding is essential for accuracy and efficiency.

Best Low-Cost Welding Clamps for SMEs:

- Magnetic welding clamps – Hold metal parts together easily.

- C-clamps and vice grips – Ideal for firmly securing workpieces.

Air Compressors for Plasma Cutting and Welding Support

For SMEs using plasma cutters or pneumatic tools, investing in an affordable air compressor is a smart move.

Best Budget-Friendly Air Compressors for SMEs:

- Maxmech 50L Air Compressor – Portable and efficient for plasma cutting.

- Maxmech 100L Air Compressor – Great for small fabrication shops.

Tip: Regularly drain moisture from air compressors to prolong their lifespan.

Bosch Angle Grinder GWS 750-115 mm Bosch

Where to Buy Affordable Welding Equipment in Nigeria

Trusted Suppliers:

Tikweld Industrial Supplies: A top supplier offering a wide selection of high-quality industrial floor paints, primers, and application tools across Nigeria, ensuring quick delivery and professional advice.

You can buy the best Epoxy Flooring materials in Nigeria from the offices below:

Tikweld Welding Supplies Port Harcourt

238 Aba Road, Onyejieke’s Plaza beside Fidelity Bank,

Rumuogba, Port Harcourt.

Tel. +234 8181069339, +234 8053390169 +234 8060907072

GZ Industrial Supplies Ikeja

18 Adesina Street, Off Obafemi Awolowo Way,

Ikeja, Lagos.

Tel. +234 8181069339, +234 7031515985, +234 8060907072

WhatsApp: +234 8181069339

GZ Industrial Supplies Lekki

Suite 10, Olive Plaza by Osapa London Bus Stop,

Lekki, Lagos

Tel. +234 8181069339, +234 8053390169 +234 8060907072

GZ Industrial Supplies Apapa

10 Apapa Oshodi Expressway, Coconut Bus stop Opposite Total Jetty,

Apapa, Lagos

Tel. +234 8181069339, +234 7031515985, +234 8060907072

GZ Industrial Supplies Calabar

30/32 Ndidem Usang Iso Road,

Marian, Calabar.

Tel. +234 8181069339, +234 8053390169 +234 8060907072

GZ Industrial Supplies ABuja

Shop 016, Zitel Plaza, Plot 227 P.O.W. Mafemi Cres. Utako, Abuja

Tell. +234 8053390161,+234 9121740191

GZ Industrial Supplies Ogba

79 Yaya Abatan, by College Road

Ogba, Lagos

Tel. +234 8181069339, +234 8053390169 +234 8060907072

Hellog Welding Oxygen MAPP gas Cylinder Torch Kit.

Leasing vs. Buying Welding Equipment

For SMEs with budget constraints, leasing can be an affordable alternative to buying expensive equipment.

When Leasing is a Good Option:

- For startups with limited capital.

- When welding needs are seasonal or project-based.

- When testing a new welding process before committing to a purchase.

Tip: Some authorized suppliers offer financing options for SMEs.

Tips for Maintaining Affordable Welding Machines

Regular maintenance ensures longevity and performance of your welding equipment.

Regular Cleaning and Inspection

- Remove dust and debris from the welding machine.

- Clean welding nozzles and torches for smooth operations.

- Check cables and connections for signs of wear.

Tip: Store electrodes and filler rods in dry areas to prevent moisture damage.

Preventing Overheating

- Allow cooling breaks during extended use.

- Ensure proper ventilation when welding indoors.

- Use thermal overload protection features when available.

Tip: Keep the cooling fans in your welder clean to prevent overheating.

Proper Storage of Welding Accessories

- Keep welding machines in a dry, dust-free area.

- Store gas cylinders in well-ventilated spaces.

- Use proper racks or shelves for consumables.

Tip: Label consumables properly to avoid mixing incompatible materials.

Affordable Spare Parts and Repairs

- Buy replacement parts from trusted suppliers.

- Service your welding machine regularly to avoid costly breakdowns.

- Use original parts to maintain machine efficiency.

Tip: Keep a backup set of essential spare parts to prevent unexpected downtime.

Frequently Asked Questions

1. What are the most affordable welding machines for small businesses in Nigeria?

Some budget-friendly options include inverter welders, arc welders, and MIG welders from brands like Maxmech, Lincoln Electric, and PowerFlex. These provide reliable performance at a lower cost.

2. How can I ensure quality when buying affordable welding equipment?

Look for trusted brands, check product reviews, and purchase from reputable suppliers like Tikweld Welding Supplies to ensure durability and efficiency.

3. What welding equipment is essential for a small business?

Basic welding equipment includes a welding machine, electrodes, protective gear (helmet, gloves, and apron), and a grinding machine for surface preparation.

4. Can I get financing options for welding equipment in Nigeria?

Yes, some suppliers and financial institutions offer installment payment plans or business loans to help SMEs acquire welding equipment.

5. Where can I buy affordable welding equipment in Nigeria?

You can purchase high-quality and budget-friendly welding equipment from Tikweld Welding Supplies, a trusted supplier in Nigeria.

Related Articles

Buying Industrial Welding Equipment: What You Need to Know

Welding Safety Gear: Protecting Workers on Industrial Floor Projects

Advanced Welding Techniques for Heavy-Duty Industrial Flooring

Conclusion

Investing in affordable yet reliable welding equipment is crucial for SMEs looking to enhance productivity while staying within budget. By selecting durable machines from reputable brands and maintaining them properly, small businesses can ensure long-term efficiency and cost savings.

Are you looking for high-quality, affordable welding equipment for your business? VisitTikweld Welding Supplies today to explore a wide range of cost-effective welding machines and accessories tailored for SMEs in Nigeria!