Top Industrial Paint Sprayers in Nigeria for Fabrication Experts

Introduction

In metal fabrication, a high-quality finish is just as important as structural strength. Whether you’re coating structural steel beams, tanks, machine parts, or metal frames, using the right paint sprayer can drastically improve productivity, surface finish, and durability.

Nigeria's fabrication industry is growing fast from oil & gas support structures to commercial construction and manufacturing and the demand for high-performance paint sprayers is increasing. Fabricators are seeking sprayers that offer efficiency, power, and versatility while withstanding harsh industrial environments.

In this article, we explore the top industrial paint sprayers available in Nigeria, made specifically to meet the needs of fabrication experts. Do you operate a large fabrication shop or handle field coating jobs, this guide will help you make an informed decision.

Read more...The Best Airless Sprayers in Nigeria 2024 Review

Key Takeaway

- Efficiency & Precision – Industrial paint sprayers provide even, smooth coatings, reducing paint waste and application time.

- Versatility – Suitable for a wide range of fabrication projects, including metal, wood, and industrial surfaces.

- Durability & Performance – High-quality sprayers ensure long-lasting performance, even under heavy-duty use.

- Types of Sprayers – Choose from airless, HVLP, and compressed air sprayers based on your specific project needs.

Big Power Airless Sprayer HVBAN EP850TX

Why Fabricators Need Specialized Paint Sprayers

Fabrication professionals face unique challenges when applying protective and aesthetic coatings. Unlike painters working on flat walls or furniture, fabricators deal with:

- Complex metal surfaces

- Sharp corners and weld joints

- Heavy-duty substrates

- High-viscosity coatings like epoxy, zinc primers, and enamel paints

Using substandard sprayers or manual application methods (like brushes or rollers) leads to:

- Inconsistent coating thickness

- Longer application times

- Increased material waste

- Poor protection against corrosion and environmental damage

Benefits of Using Industrial Paint Sprayers for Fabrication:

- Uniform application across rough or welded surfaces

- Faster coverage, reducing labor time

- Better atomization of thick coatings like primers and zinc-rich paints

Compatibility with multi-gun setups, allowing more than one operator to spray simultaneously

Key Features to Look for in a Paint Sprayer for Fabrication Work

Before selecting a paint sprayer, here are essential features fabrication experts should prioritize:

High Pressure Output

You’ll need at least 20–23 MPa (2900–3300 PSI) for most industrial coatings to atomize properly. Higher pressure ensures penetration into welded areas and rough surfaces.

High Flow Rate

A sprayer with 4–8 liters per minute allows fast coverage over beams, plates, and pipes, reducing turnaround time.

Industrial Durability

Look for sprayers with stainless steel or hardened components, gear grinding, and INA bearings that can survive dust, rust, and long-duty cycles.

Coating Compatibility

Ensure the sprayer handles solvent-based paint, epoxy, zinc-rich primers, enamels, and other protective coatings commonly used in fabrication.

Portability

For on-site fabrication or steel erection jobs, opt for petrol-powered sprayers or units mounted on trolleys for easier mobility.

Multi-Gun Functionality

Some high-end models support two spray guns simultaneously, allowing teams to work faster and complete larger projects in less time.

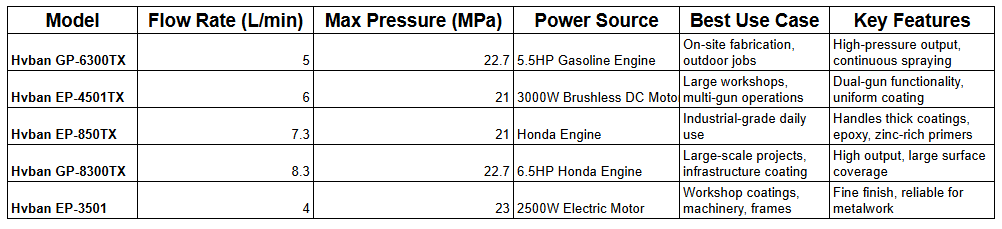

Comparison Table: Top Industrial Paint Sprayers for Fabrication Experts in Nigeria

Top Industrial Paint Sprayers in Nigeria (Recommended Models)

Below are some of the most reliable industrial paint sprayers available in Nigeria, particularly suited for fabrication workshops and on-site projects. These models are stocked by Tikweld Products and Services and are known for durability, output power, and coating versatility.

Hvban GP-6300TX – Powerful Petrol Sprayer for Large Fabrication Jobs

- Flow Rate: 5 L/min

- Max Pressure: 22.7 MPa

- Nozzle Size: 0.033”

- Power Source: 5.5HP Gasoline Engine

- Why It’s Ideal: This petrol-powered sprayer is perfect for outdoor fabrication sites without power supply. It delivers high-pressure output to handle thick protective coatings and ensures continuous spraying for long hours.

Hvban EP-4501TX – Electric Dual-Gun Sprayer for Speed and Efficiency

- Flow Rate: 6 L/min

- Max Pressure: 21 MPa

- Power Source: 3000W Brushless DC Motor

- Nozzle Sizes: 0.037” (1 gun), 0.027” (2 guns)

- Why It’s Ideal: Ideal for large-scale fabrication or painting operations where two spray operators are required. Great for workshops that prioritize efficiency and uniformity on fabricated steel surfaces.

Airless Sprayer MARK V Type HVBAN EP450ITX

Hvban EP-850TX – Heavy-Duty Daily Use Sprayer

- Flow Rate: 7.3 L/min

- Max Pressure: 21 MPa

- Power Source: Honda Engine

- Nozzle Sizes: 0.039” (1 gun), 0.029” (2 guns)

- Why It’s Ideal: Built for industrial-grade continuous use, this model handles epoxy, zinc-rich primers, and elastomeric coatings. It’s an excellent fit for daily fabrication shop operations or large-scale infrastructure coating jobs.

Hvban GP-8300TX – Maximum Output for Industrial Fabrication

- Flow Rate: 8.3 L/min

- Max Pressure: 22.7 MPa

- Power Source: 6.5HP Honda Engine

- Nozzle Size: 0.047”

- Why It’s Ideal: This high-output sprayer is suited for massive fabrication projects. It covers large surfaces quickly, making it suitable for warehouses, bridges, or container yards.

Hvban EP-3501 – Versatile Electric Sprayer for Workshop Coatings

- Flow Rate: 4.0 L/min

- Working Pressure: 23 MPa

- Power Source: 2500W Electric Motor

- Nozzle Size: 0.033”

- Why It’s Ideal: Great for workshops handling machinery, frames, and fabricated equipment. Offers fine finish, reliability, and can be used for furniture and general metalwork coatings as well.

Best Use Cases for These Paint Sprayers in Fabrication

These paint sprayers are not just powerful — they’re engineered for real-world fabrication environments. Here are common use cases:

- Structural Steel Coating: Beams, columns, girders

- Skid and Platform Spraying: Used in oil & gas fabrication

- Weld Joint Protection: Apply anti-rust primers and epoxy on welded areas

- Tanks and Silos: High-output models are perfect for coating large, round metal surfaces

- Metal Fencing and Frames: For fencing contractors and metal product manufacturers

- Heavy Equipment Fabrication: Bulldozers, graders, trailers, marine equipment

Insight: Paint sprayers help fabricators meet quality assurance standards faster, especially when dealing with tight delivery deadlines or multi-coat systems.

Gasoline Airless Paint Sprayer HVBAN GP8300TX

Maintenance Tips for Industrial Paint Sprayers

Proper maintenance of your paint sprayer ensures consistent performance, longer equipment life, and reduced project delays. Here’s what fabrication experts should keep in mind:

Clean After Every Use

- Epoxy, primers, and solvent-based coatings harden quickly and can clog the system.

- Flush the machine with the appropriate cleaning solvent (e.g., xylene or water, depending on coating type).

Inspect and Replace Filters

- Clogged or worn-out filters reduce flow and pressure, leading to uneven spraying.

- Replace inline filters, tip strainers, and manifold filters regularly.

Lubricate Moving Parts

- Pistons, seals, and motor components require periodic lubrication to avoid seizing or wear.

Check for Hose Leaks and Pressure Drops

- Always inspect hoses before spraying. A damaged hose under high pressure can be dangerous.

Store in a Clean, Dry Place

- Protect your machine from dust, moisture, and heat. Cover it after use and avoid storage with leftover paint inside.

Pro Tip: Schedule routine servicing based on your workload. If your fabrication shop runs daily, consider a monthly full check-up.

HVBAN Petrol Airless Sprayer GP6300 (TX)

Frequently Asked Questions

1. What is the best paint sprayer for zinc-rich primers in fabrication work?

Hvban GP-8300TX or EP-850TX are top choices due to their high flow rate and pressure capabilities, ideal for viscous coatings like zinc-rich primers.

2. Can I use a paint sprayer for both interior and exterior fabricated metal structures?

Yes, especially if you’re using an airless sprayer. Just ensure the right nozzle and pressure settings for the coating and surface type.

3. Are electric or petrol-powered paint sprayers better for fabrication experts?

Petrol-powered sprayers like GP-6300TX are ideal for mobile/on-site jobs without power access. Electric models like EP-4501TX are best for consistent indoor or workshop use.

4. How do I prevent clogging when spraying epoxy or thick paints?

Use correct tip sizes, strain the paint, and clean the sprayer immediately after use. Regular maintenance prevents most clogging issues.

5. Where can I get replacement parts or servicing in Nigeria?

Tikweld Products and Services offers genuine parts, servicing, and professional guidance for all your industrial paint sprayers.

Related Articles

How to set up air compressor for paint spraying

Types of Industrial Painting Techniques: Choosing the Right Approach for Your Facility

How to Choose the Best Paint Sprayer for Professional and DIY Projects in Nigeria

Conclusion

In today’s fast-paced fabrication industry, precision, efficiency, and durability are non-negotiable. Investing in a reliable industrial paint sprayer can be the difference between delivering a professional-grade product on time — or falling behind schedule.

With models like the Hvban GP-6300TX, EP-850TX, and EP-3501, fabrication experts in Nigeria can now access high-performance tools built for their unique challenges. Whether you’re coating structural steel, spraying protective finishes, or working on-site in remote areas, there’s a sprayer that fits your need — and it’s available right here in Nigeria.

Enhance your fabrication projects with top-quality industrial paint sprayers designed for precision, efficiency, and durability. Whether you need a sprayer for metal coatings, large-scale industrial applications, or fine detailing, we have the right solution for you. Explore our collection of industrial paint sprayers now! Visit Tikweld Welding Supplies to find the perfect sprayer for your needs.