Benefits of Using Paint Sprayers in Tank Fabrication Projects

Introduction

Tank fabrication is a critical aspect of Nigeria’s industrial growth, especially across sectors such as oil and gas, water treatment, chemical processing, and agriculture. These tanks, whether built for fuel, water, or chemical storage must not only be structurally sound but also protected with industrial-grade coatings that resist corrosion, chemicals, UV, and other environmental factors.

While manual application methods like brushing or rolling have traditionally been used, paint sprayers have rapidly become the tool of choice for fabricators due to their speed, precision, and superior finish. In tank fabrication projects where time, consistency, and protective performance are critical, sprayers deliver a measurable advantage.

Read more...Top Industrial Paint Sprayers in Nigeria for Fabrication Experts

Key Takeaway

-

Superior Coating Quality – Paint sprayers provide smooth, uniform, and even coverage, reducing the risk of streaks, drips, and uneven application.

-

Increased Efficiency & Speed – Sprayers apply coatings much faster than brushes or rollers, significantly reducing labor time and project duration.

-

Enhanced Corrosion Protection – Industrial tanks require high-quality coatings to resist rust, chemicals, and environmental damage; sprayers ensure proper adhesion for long-lasting protection.

Challenges in Coating Fabricated Tanks

Painting a fabricated tank is far more complex than it seems. Whether the tank is horizontal, vertical, elevated, or underground, fabricators and coating specialists often face:

- Large, curved surfaces that require even and consistent coating

- Internal linings where access is restricted and safety is a concern

- Sharp angles, weld seams, and surface irregularities

- The need to apply high-build coatings (such as epoxy, polyurethane, or zinc primers)

- Strict project timelines with little margin for rework or delay

Manual methods like brushes or rollers often fall short in addressing these challenges. They’re time-consuming, prone to errors in film thickness, and often leave brush marks or inconsistent finishes.

This is where industrial paint sprayers prove invaluable.

Why Paint Sprayers Are Ideal for Tank Fabrication Projects

Faster Application Over Large Surfaces

Industrial tanks are huge, ranging from 1,000 to 50,000 liters or more. Covering such a large area manually can take days. Paint sprayers, especially airless and piston models, can cover these surfaces in a fraction of the time.

A paint sprayer’s high flow rate allows for rapid coverage without sacrificing coating quality, ensuring you meet tight project deadlines and reduce downtime.

Uniform Coating Thickness

In tank fabrication, achieving the correct dry film thickness (DFT) is essential to ensure long-term protection from corrosion, especially in harsh environments like coastal areas or chemical plants.

Paint sprayers are capable of delivering consistent and controlled layers of coating, minimizing the risk of:

- Undercoating (which exposes the surface to corrosion)

- Overcoating (which wastes material and increases cost)

Improved Adhesion in Hard-to-Reach Areas

Weld seams, stiffeners, nozzles, flanges, and corners are notoriously difficult to coat uniformly with a brush. With the right spray tip and angle, paint sprayers can easily access:

- Complex geometries

- Interior curves

- Narrow gaps

This ensures better adhesion and coverage, which is critical for tanks holding corrosive or pressurized contents.

Airless Sprayer MARK V Type HVBAN EP450ITX

Efficient Use of High-Performance Coatings

Tank coatings often include:

- Zinc-rich primers

- Polyurethane topcoats

- Epoxy linings

- Solvent- or water-based DTM (direct-to-metal) coatings

These are thick and viscous and can be difficult to apply by brush. Paint sprayers—especially high-pressure airless models like the Hvban GP-8300TX or EP-850TX—are engineered to atomize and apply these coatings evenly, even at higher viscosities.

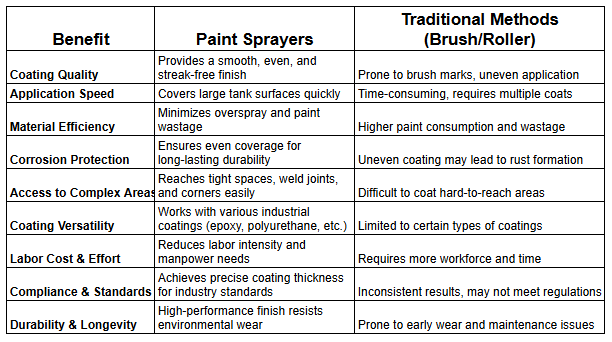

Comparison of Benefits: Paint Sprayers vs. Traditional Methods in Tank Fabrication

Read more...The Best Airless Sprayers in Nigeria 2024 Review

Paint Sprayer Types Best Suited for Tank Fabrication

Choosing the right type of sprayer is key to maximizing efficiency in tank coating. Here are the top types used in industrial fabrication:

Airless Paint Sprayers

Airless sprayers are the industry standard for large-scale projects like tank fabrication. They work by pumping paint at high pressure (up to 3300 PSI) through a small nozzle to atomize the coating without the need for compressed air.

- Best for: External tank surfaces, epoxy and high-viscosity coatings

- Advantages: Fast application, thick coating capacity, consistent finish

- Example Model: Hvban EP-850TX or GP-8300TX (gasoline version for remote sites)

Electric Piston Paint Sprayers

Electric sprayers like the Hvban EP-3501 or EP-4501TX are ideal for controlled environments such as fabrication workshops. Their piston system builds high pressure and maintains spray consistency.

- Best for: Mid-sized fabrication shops or indoor tank prep

- Advantages: Smooth operation, low noise, better control, two-gun capability for larger teams

HVBAN Petrol Airless Sprayer GP6300 (TX)

Petrol-Powered Sprayers

When working in off-grid locations or large outdoor yards where power supply is unstable or unavailable, petrol sprayers offer full independence.

- Best for: On-site tank jobs in remote or industrial zones

- Advantages: No power limitation, durable, suited for heavy industrial use

- Example Model: Hvban GP-6300TX or GP-8300TX

HVLP (High Volume Low Pressure) Sprayers

While not ideal for entire tank jobs, HVLP sprayers are excellent for detail work—such as finishing touch-ups, applying topcoats, or coating tank components like flanges and access covers.

Cost and Time Savings with Paint Sprayers

Time Efficiency

Manual coating methods for a 10,000-liter tank may take 3–5 days. A powerful paint sprayer can reduce that time to under 1 day, depending on surface complexity and team size.

Reduced Labor Costs

- Fewer workers needed for the same job

- Faster completion = more projects per month

- Reduced fatigue and rework, enhancing safety and efficiency

Material Savings

Sprayers deliver controlled, even coverage, reducing:

- Overspray

- Dripping or pooling

- Material waste due to uneven layering

Real-World Applications

Paint sprayers play a vital role in multiple tank-related fabrication and coating projects:

- Oil and gas tank farms – External epoxy and zinc-rich coating systems

- Chemical and water storage tanks – Interior lining with corrosion-resistant epoxy

- Marine vessels and fuel tanks – Dual-component spray systems

- Agricultural fertilizer tanks – Spray-applied sealants for chemical resistance

- Firefighting reserve tanks – UV-resistant polyurethane finishes

These applications demand both performance and speed — attributes that manual methods can’t deliver consistently in today’s competitive industrial climate.

Electric Piston Airless Sprayer HVBAN EP350I

Maintenance and Best Practices

To maximize the performance and lifespan of your paint sprayer in tank fabrication, follow these best practices:

Clean the Equipment Immediately After Use

Coatings like epoxy and zinc-rich primers harden quickly. Flush the sprayer with the appropriate solvent to prevent clogging and internal damage.

Use Proper Tip Sizes and Filters

Select spray tips suitable for high-viscosity coatings. Use filters and strainers to avoid debris that can clog the nozzle or reduce pressure consistency.

Inspect Hoses and Connections Regularly

High-pressure sprayers require durable hoses. Check for wear, leaks, or kinks before every use.

Calibrate Pressure Settings for Each Coating Type

Test spray before starting the job. Adjust pressure to achieve the correct atomization and coverage, especially for high-build systems.

Practice Safety in Confined Spaces

When spraying inside tanks, always:

- Use explosion-proof lighting and equipment

- Ensure proper ventilation

- Wear full PPE, including a respirator

Frequently Asked Questions

1. Can paint sprayers be used for both interior and exterior tank coatings?

Yes. With the right safety setup and ventilation, paint sprayers are ideal for both interior linings and exterior coatings, especially when using high-performance materials like epoxy or polyurethanes.

2. What is the best type of sprayer for zinc-rich primers in tank fabrication?

Airless sprayers like the Hvban GP-8300TX or EP-850TX are most effective for zinc-rich primers due to their high pressure and consistent atomization of thick coatings.

3. Are there safety concerns with using sprayers inside tanks?

Yes. Spraying in confined spaces requires strict safety protocols, including gas detectors, ventilation systems, PPE, and a trained operator familiar with confined space entry.

4. How do I ensure the coating thickness meets specifications?

Use a wet film thickness gauge during application and a dry film gauge after curing. Consistency is more easily achieved with a calibrated airless sprayer.

5. Where can I buy reliable industrial paint sprayers in Nigeria?

You can purchase industrial-grade paint sprayers, including models from Hvban, at

Tikweld Products and Services — a trusted distributor of fabrication equipment, coatings, and industrial tools.

Related Articles

Types of Industrial Painting Techniques: Choosing the Right Approach for Your Facility

How to Choose the Best Paint Sprayer for Professional and DIY Projects in Nigeria

Conclusion

In tank fabrication projects, achieving a smooth, uniform, and durable coating is crucial for protection against corrosion, harsh environments, and chemical exposure. Paint sprayers provide the efficiency, precision, and coverage needed to meet industrial standards while saving time and reducing material waste.

By investing in high-quality paint sprayers, fabricators can enhance productivity, improve coating adhesion, and extend the lifespan of tanks used in industries such as oil & gas, manufacturing, and water storage. Whether you need an airless sprayer for heavy-duty applications or an HVLP system for fine finishes, choosing the right equipment makes all the difference.

Upgrade your tank fabrication process with top-quality industrial paint sprayers from Tikweld Welding Supplies. Explore our collection of durable and high-performance sprayers designed to handle large-scale coating jobs efficiently. Visit Tikweld Welding Supplies today and get the best paint sprayer for your fabrication needs!